Lutherie and creative recycling

- Taffy Evans

- Blackwood

- Posts: 997

- Joined: Wed Apr 30, 2008 6:54 pm

- Location: Charters Towers North Queensland

Lutherie and creative recycling

Too damp for building and I’ve built enough jigs for one week, so its time to sit at the computer for a while, hope you find this interesting………..

I would suspect that others working in the repair and instrument building fields are an inventive mob, especially if one started building or repairing some years ago or lived and worked in remote areas of the country. For me it was a case of both of these scenarios, if you need it and can’t buy it, there must be another way. Now that I think of it “Try Another Wayâ€

I would suspect that others working in the repair and instrument building fields are an inventive mob, especially if one started building or repairing some years ago or lived and worked in remote areas of the country. For me it was a case of both of these scenarios, if you need it and can’t buy it, there must be another way. Now that I think of it “Try Another Wayâ€

Taff

What a simply fantastic post Taffy.

Thanks so much for sharing some of your story with us. I cannot wait for parts 2 and hopefully 3, 4, 5, 6 and onwards. I must say that your input adds so much to the ANZLF which gives it such an inviting and unique feel among the lutherie based Internet forums.

Cheers

Kim

Thanks so much for sharing some of your story with us. I cannot wait for parts 2 and hopefully 3, 4, 5, 6 and onwards. I must say that your input adds so much to the ANZLF which gives it such an inviting and unique feel among the lutherie based Internet forums.

Cheers

Kim

- ozziebluesman

- Blackwood

- Posts: 1529

- Joined: Wed Oct 10, 2007 9:12 am

- Location: Townsville

- Contact:

Taff, your the man! I agree with recycling and why not in Lutherie. Your neck setting jig is a ripper idea! Waiting for your next installment.

From the mid seventies I owned and operated a dairy farm for 11 years. When your out in the wilderness, miles from services you have to learn to improvise! Things go wrong, machinery breaks down and often you have to come up with innovative ways to keep the farm running. An arc welder, good vice, drill press and a large inventory of recycled nuts, bolts, screws etc kept evrything operating. Thinking with an innovative frame of mind can be very fruitful and after a while, you get damm good at it.

I haven't been building guitars for all that long and don't have all the modern tools but I sure have drawn upon those innovative days approaching problems in my guitar builds and make them work!

Cheers

Alan

From the mid seventies I owned and operated a dairy farm for 11 years. When your out in the wilderness, miles from services you have to learn to improvise! Things go wrong, machinery breaks down and often you have to come up with innovative ways to keep the farm running. An arc welder, good vice, drill press and a large inventory of recycled nuts, bolts, screws etc kept evrything operating. Thinking with an innovative frame of mind can be very fruitful and after a while, you get damm good at it.

I haven't been building guitars for all that long and don't have all the modern tools but I sure have drawn upon those innovative days approaching problems in my guitar builds and make them work!

Cheers

Alan

- DarwinStrings

- Blackwood

- Posts: 1877

- Joined: Thu Nov 13, 2008 10:27 pm

- Location: Darwin

Great stuff Taffy. You started a bit before me as that banjo pic was taken when I was turning one year old.

I started on a low budget and when the convenience of the PC was not sitting in front of me. So information was replaced by improvisation.

For my first mandolin I bought nothing from a guitar part or guitar wood supplier except for the strings. All the tools used were from my carpentry kit and the rest were improvised, smoothing the edge of a triangular file to dress fretts, a old chisel cut at 45 degrees and sharpened for a skew chisel and the piece of malleable galvanised water pipe that is still in use for side bending today.

Your post really strikes a chord. I am now hoping that it remains a little damp in Charters Towers so you can get a bit more writting done.

Jim

I started on a low budget and when the convenience of the PC was not sitting in front of me. So information was replaced by improvisation.

For my first mandolin I bought nothing from a guitar part or guitar wood supplier except for the strings. All the tools used were from my carpentry kit and the rest were improvised, smoothing the edge of a triangular file to dress fretts, a old chisel cut at 45 degrees and sharpened for a skew chisel and the piece of malleable galvanised water pipe that is still in use for side bending today.

Your post really strikes a chord. I am now hoping that it remains a little damp in Charters Towers so you can get a bit more writting done.

Jim

- Taffy Evans

- Blackwood

- Posts: 997

- Joined: Wed Apr 30, 2008 6:54 pm

- Location: Charters Towers North Queensland

Thanks for the support all, as you think this type of post is interesting I've started part two, possibly room for 5-6, but not so wordy maybe. Question: Should I call it part two in a new post, or keep them all in this thread.

Thanks.

oh I cant help myself........

Why????? Must be too much wet weather or something

Thanks.

oh I cant help myself........

Why????? Must be too much wet weather or something

Taff

I don't care if you start another with called part 2 or one long one Taffy. We'll all find them one way or the other.

One quick question. I've heard that you've got a fair bit of experience working with people with physical / mental challenges, disabilities. Whatever the politically correct term is today. I'm wondering if you've got any tips for me with loosing everything I seem to put my bloody hands on in my shop. It might just be my age creeping up, but bloody hell it's getting frustrating.

Perhaps a wheelie cart to drag about and place things in if I've got an urge to pick something up.

One quick question. I've heard that you've got a fair bit of experience working with people with physical / mental challenges, disabilities. Whatever the politically correct term is today. I'm wondering if you've got any tips for me with loosing everything I seem to put my bloody hands on in my shop. It might just be my age creeping up, but bloody hell it's getting frustrating.

Perhaps a wheelie cart to drag about and place things in if I've got an urge to pick something up.

- Taffy Evans

- Blackwood

- Posts: 997

- Joined: Wed Apr 30, 2008 6:54 pm

- Location: Charters Towers North Queensland

Allen, if you are losing things you've got your hands on there's no hope, if you are losing things you have'nt got your hands on the there is a chance.

For me though the tools I use are put back in the respective spaces if they are not needed again even if the job is not finished.

Many of my tools are close at hand and go back in the rack after every use. I took a photo the other week of my bench after a pretty challenging refret as I could not believe the number of tools I had dragged out over the hours spent on the job. This was followed by another fret job, but before starting it I put all the tools from the first job away, and started again..........maybe I need the help

For me though the tools I use are put back in the respective spaces if they are not needed again even if the job is not finished.

Many of my tools are close at hand and go back in the rack after every use. I took a photo the other week of my bench after a pretty challenging refret as I could not believe the number of tools I had dragged out over the hours spent on the job. This was followed by another fret job, but before starting it I put all the tools from the first job away, and started again..........maybe I need the help

Taff

- Taffy Evans

- Blackwood

- Posts: 997

- Joined: Wed Apr 30, 2008 6:54 pm

- Location: Charters Towers North Queensland

- Taffy Evans

- Blackwood

- Posts: 997

- Joined: Wed Apr 30, 2008 6:54 pm

- Location: Charters Towers North Queensland

Part 2...........

In part two of creative use of resources [recycling] I have shown some of the things I have made out of born again materials. I have always found the kitchen/house has an endless supply of goodies suitable for adaptation to the needs of the builder/repairer. My wife has often come out to my workshop asking “where did that come from?â€

In part two of creative use of resources [recycling] I have shown some of the things I have made out of born again materials. I have always found the kitchen/house has an endless supply of goodies suitable for adaptation to the needs of the builder/repairer. My wife has often come out to my workshop asking “where did that come from?â€

Taff

- sebastiaan56

- Blackwood

- Posts: 1279

- Joined: Sun Oct 28, 2007 5:23 am

- Location: Blue Mountains

- DarwinStrings

- Blackwood

- Posts: 1877

- Joined: Thu Nov 13, 2008 10:27 pm

- Location: Darwin

I thought I might try to beat you to this one Taffy as I would gamble that you have a bit of this hanging around your shed somewhere.

This would be my favorite and perhaps most used piece of recycled material that I posses. Old truck tyres are handy for many things, I use them for the tyres on my band saw as well as anything that needs a bit of firm cushioning. Best to source them in the dry season up here though so you don't have to compete with the kids that want them to use in the swollen creeks this time of year.

They work very well when you need to clamp difficult shapes. This is a recent neck repair job on a shell back mandolin.

Jim

This would be my favorite and perhaps most used piece of recycled material that I posses. Old truck tyres are handy for many things, I use them for the tyres on my band saw as well as anything that needs a bit of firm cushioning. Best to source them in the dry season up here though so you don't have to compete with the kids that want them to use in the swollen creeks this time of year.

They work very well when you need to clamp difficult shapes. This is a recent neck repair job on a shell back mandolin.

Jim

- Taffy Evans

- Blackwood

- Posts: 997

- Joined: Wed Apr 30, 2008 6:54 pm

- Location: Charters Towers North Queensland

Thanks Taffy,

All good stuff but man I just gotta say, I have held heaps on those Moccona coffee jars in my hand. I have even popped the plastic seal from the top to have a look, but it never dawned on me to use the lid as a small wide mouthed jar and the plastic seal as a lid. That is just brilliance

Cheers

Kim

All good stuff but man I just gotta say, I have held heaps on those Moccona coffee jars in my hand. I have even popped the plastic seal from the top to have a look, but it never dawned on me to use the lid as a small wide mouthed jar and the plastic seal as a lid. That is just brilliance

Cheers

Kim

-

Connor_the_builder

- Beefwood

- Posts: 20

- Joined: Wed Jan 21, 2009 9:20 pm

- Taffy Evans

- Blackwood

- Posts: 997

- Joined: Wed Apr 30, 2008 6:54 pm

- Location: Charters Towers North Queensland

-

Connor_the_builder

- Beefwood

- Posts: 20

- Joined: Wed Jan 21, 2009 9:20 pm

- Hippety Hop

- Blackwood

- Posts: 175

- Joined: Wed Apr 30, 2008 11:18 am

- Location: Moorabbin

- Taffy Evans

- Blackwood

- Posts: 997

- Joined: Wed Apr 30, 2008 6:54 pm

- Location: Charters Towers North Queensland

- Taffy Evans

- Blackwood

- Posts: 997

- Joined: Wed Apr 30, 2008 6:54 pm

- Location: Charters Towers North Queensland

I hope this is the one......

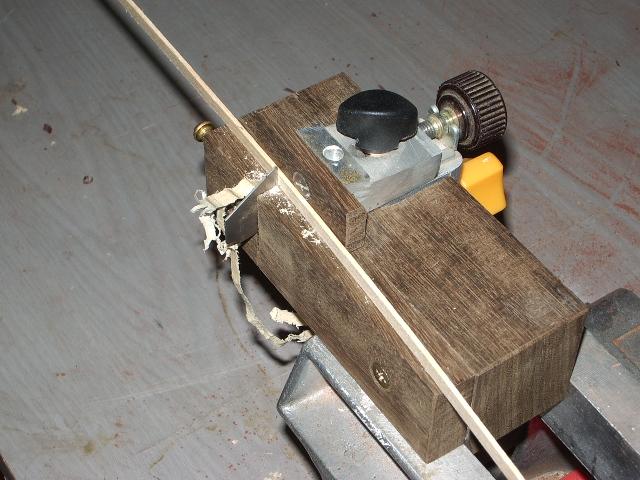

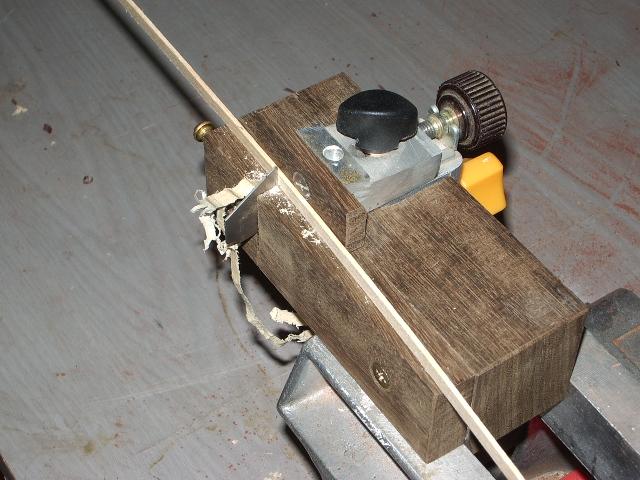

G’day Lillian, here’s a bit more on the binding thicknesser you asked about.

The fittings are from a Makita trimmer, the yellow knob holds the fitting to the main wood body

The knob above that is the fine adjustment of cut

The knob above that is the locking screw that locks the fence in place

The brass screw is threaded into the timber body and makes contact with the blade and locks it in place, a box cutter or Stanley knife blade in this case.

It could be made much simpler with the fence being locked down by two wing nuts [a piece of hardwood with two slots in it to allow adjustment]. As one needs to take fine cuts [as I get chatter, but this could be alleviated by mounting the blade more firmly I suspect] the micro adjustment makes it more user friendly anyway.

I made it for use with some plastic binding that I had to use on a couple of guitars, I don’t use plastic unless I really have to, but with some repairs I do.

G’day Lillian, here’s a bit more on the binding thicknesser you asked about.

The fittings are from a Makita trimmer, the yellow knob holds the fitting to the main wood body

The knob above that is the fine adjustment of cut

The knob above that is the locking screw that locks the fence in place

The brass screw is threaded into the timber body and makes contact with the blade and locks it in place, a box cutter or Stanley knife blade in this case.

It could be made much simpler with the fence being locked down by two wing nuts [a piece of hardwood with two slots in it to allow adjustment]. As one needs to take fine cuts [as I get chatter, but this could be alleviated by mounting the blade more firmly I suspect] the micro adjustment makes it more user friendly anyway.

I made it for use with some plastic binding that I had to use on a couple of guitars, I don’t use plastic unless I really have to, but with some repairs I do.

Taff

Who is online

Users browsing this forum: No registered users and 260 guests