Dovetail neck join

- John Steele

- Blackwood

- Posts: 152

- Joined: Fri Mar 06, 2009 4:58 pm

- Location: Wilson, NY. 14172

- Contact:

Dovetail neck join

This is how I go about joining a neck and body. I use a basic dovetail joint created with a router, dovetail bit, and jigs. The jigs I use are based on the Don Teeter’s jigs from his 2nd book from a while back. I use the 5/8â€

"People who say it cannot be done should not interrupt those who are doing it"

George Bernard Shaw

George Bernard Shaw

- Hippety Hop

- Blackwood

- Posts: 175

- Joined: Wed Apr 30, 2008 11:18 am

- Location: Moorabbin

- John Steele

- Blackwood

- Posts: 152

- Joined: Fri Mar 06, 2009 4:58 pm

- Location: Wilson, NY. 14172

- Contact:

The side angle of the jigs is right at 80 deg. I could Email/post a full size jpg of my jig drawing that fits on a 8 1/2 X 11 sheet. I just glue the print out onto the sheet stock (I use 3/8" ply) & cut/drill.

Yes, racking/rocking to me mean the same. The neck & body lock in and any side or downward pressure does not create any movement.

Yes, racking/rocking to me mean the same. The neck & body lock in and any side or downward pressure does not create any movement.

"People who say it cannot be done should not interrupt those who are doing it"

George Bernard Shaw

George Bernard Shaw

- John Steele

- Blackwood

- Posts: 152

- Joined: Fri Mar 06, 2009 4:58 pm

- Location: Wilson, NY. 14172

- Contact:

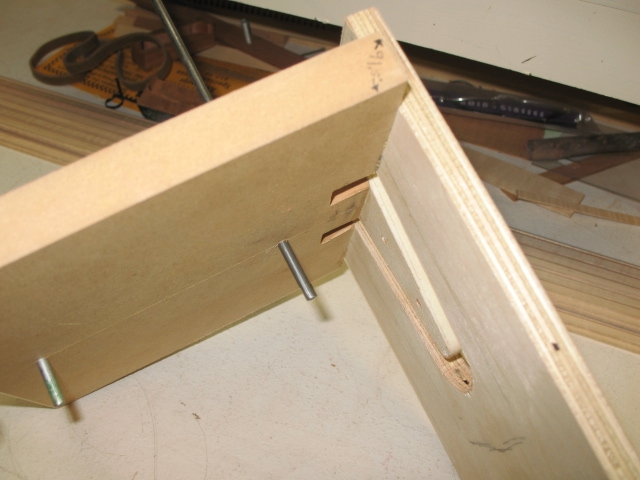

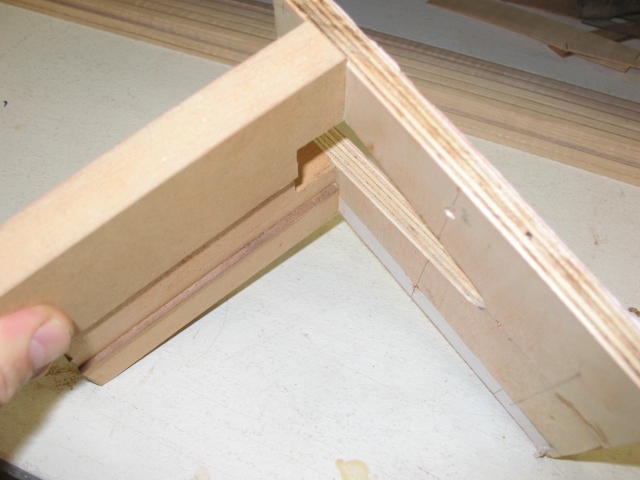

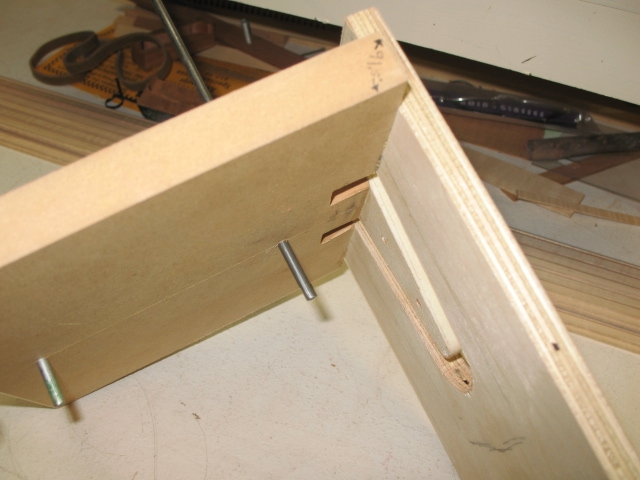

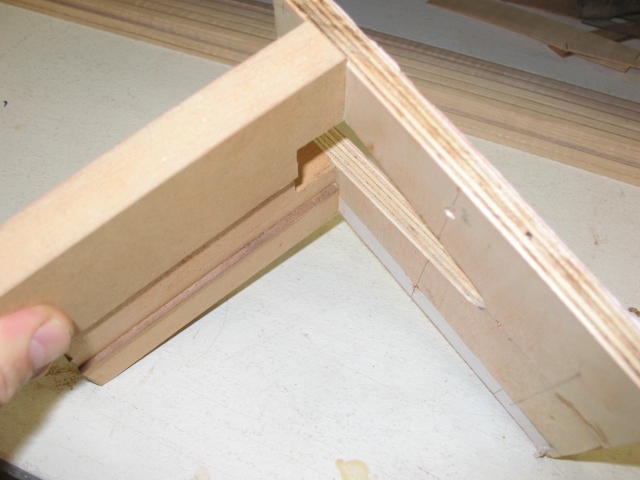

Bob was kind enough to upload the pdf's onto the server. Basically print out full size (no scaling) onto 8.5 X 11 letter size sheet and glue onto sheet stock (I use 3/8") and cut away. Next I add a fence at 90 deg for the female and 91.5 deg on the male. For the male I just joint (rip on saw would work too) the top edge at the 91.5 deg and attach. Here on some more pics to show the finished product.

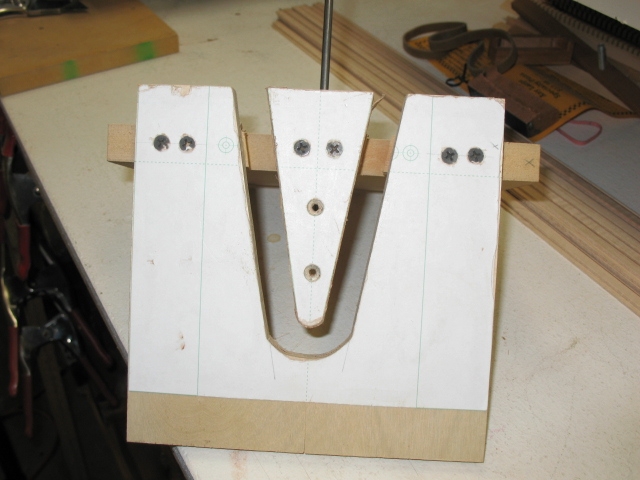

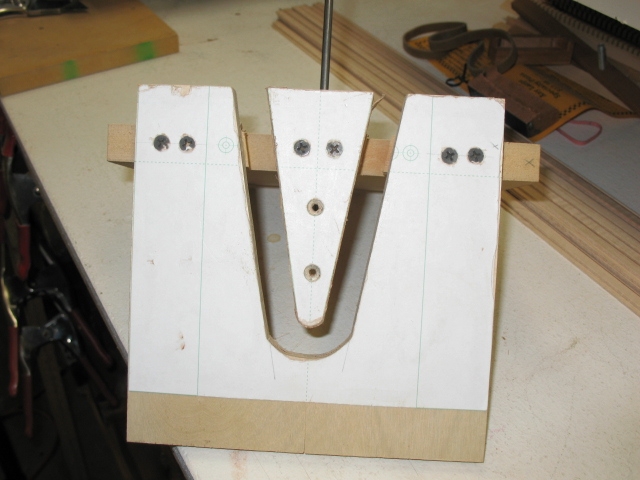

Male side jig:

The pins you see drop into my truss slot for alignment

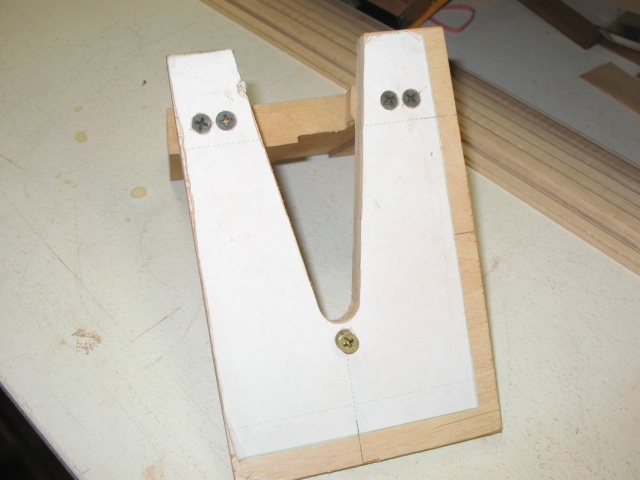

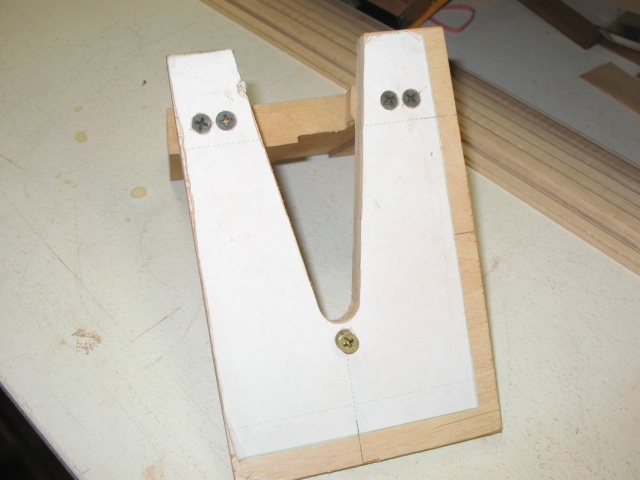

Female side jig

If you want to make adjustments for fit, you can cut either the female side opening smaller, or the male side larger. I have used masking tap on the male side to increase its dimensions. I highly recommend cutting some practice joints on scrap stock until you get the fit you want. After that it is all aligning the jigs along a common center line.

Thx Bob

J

Male side jig:

The pins you see drop into my truss slot for alignment

Female side jig

If you want to make adjustments for fit, you can cut either the female side opening smaller, or the male side larger. I have used masking tap on the male side to increase its dimensions. I highly recommend cutting some practice joints on scrap stock until you get the fit you want. After that it is all aligning the jigs along a common center line.

Thx Bob

J

"People who say it cannot be done should not interrupt those who are doing it"

George Bernard Shaw

George Bernard Shaw

- John Steele

- Blackwood

- Posts: 152

- Joined: Fri Mar 06, 2009 4:58 pm

- Location: Wilson, NY. 14172

- Contact:

duh, the links for the pdfs...

Male: http://www.connor.net.au/malejig.pdf

Female: http://www.connor.net.au/femalejig.pdf

Male: http://www.connor.net.au/malejig.pdf

Female: http://www.connor.net.au/femalejig.pdf

"People who say it cannot be done should not interrupt those who are doing it"

George Bernard Shaw

George Bernard Shaw

- Hippety Hop

- Blackwood

- Posts: 175

- Joined: Wed Apr 30, 2008 11:18 am

- Location: Moorabbin

Well you got me going.

I reduced to suit soprano and concert ukes. I got my bit from Carbi-tool, where I ran into Max from C&S Saw Blades. Funny, it was them that put me onto him a year or two ago.

The bit cuts a depth of 10mm (3/8"), which is plenty. The bearing is 12.6mm dia., so I'll try making the male jig slot 13 mm wide.

Anyway, cheers and thanks for the plans.

Hip.

I reduced to suit soprano and concert ukes. I got my bit from Carbi-tool, where I ran into Max from C&S Saw Blades. Funny, it was them that put me onto him a year or two ago.

The bit cuts a depth of 10mm (3/8"), which is plenty. The bearing is 12.6mm dia., so I'll try making the male jig slot 13 mm wide.

Anyway, cheers and thanks for the plans.

Hip.

[img]http://planetsmilies.net/not-tagged-smiley-10140.gif[/img][img]http://planetsmilies.net/person-smiley-1062.gif[/img]

Hippus Erectus

Hippus Erectus

-

Joe Sustaire

- Myrtle

- Posts: 92

- Joined: Sun Nov 23, 2008 1:23 am

- Location: Talihina Oklahoma

- Contact:

This is super John! I've been wanting to try the dovetail neck joint and this is just the toot to get me started. I've just used mortice and tenon bolt-on joints so far, but since I seem to be fixated on 12 fret vintage body shapes it just seems I ought to get familiar with dovetails.

Thanks again John for this toot and patterns,

Joe

Thanks again John for this toot and patterns,

Joe

The only safe thing to do, is to take a chance! Mike Nichols

Who is online

Users browsing this forum: No registered users and 11 guests