Although the greater majority of you are Acoustic builders I thought you may be interested in some photos of my latest guitar - as I have used CNC for this model. I have been refining this shape and have recently made some minor design changes to the top contour.

I have some YouTube clips of the guitar in action. Jordan is the new owner and I custom built this for him. The 12th fret inlay features a MoP design of the tattoo on his left arm. We wanted to try and really personalise the guitar and decided this was the best way. The guitar also features a L.R.Baggs Piezo Tremolo bridge. I tried to do something a little bit different with the burst finish to make it a little bit more intense.

http://www.jbguitars.com.au/youtube.html

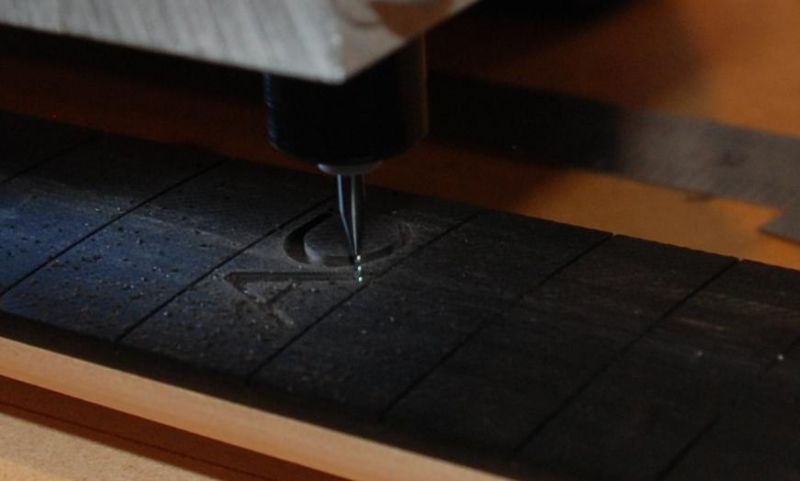

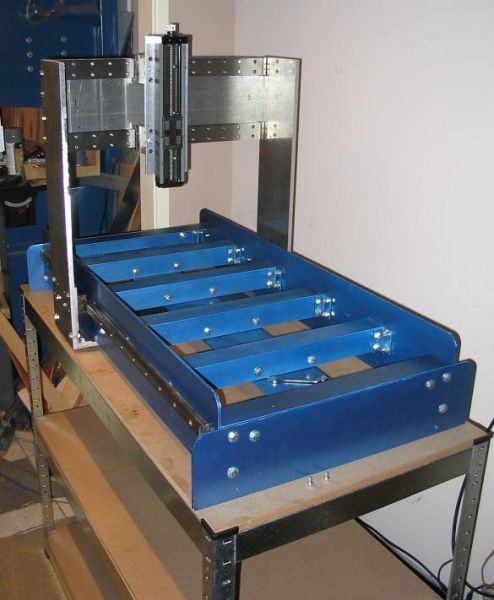

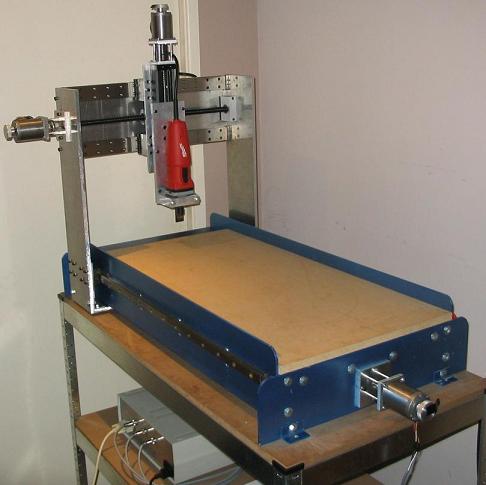

You will also see in the clip a video of a top being carved by CNC. I have only recently started carving my tops this way. I designed the top in 3D CAD and the carve took about an hour and a half (sped up to 4 mins on the clip). The base profile and curves for the neck were also CNCed. I have been using CNC for my guitars for a few years now but only for 2D profiling pocketing and Inlay work.

I have another Artist model guitar in progress at the moment which will be shipped off overseas to it's new owner in few weeks. I will post photos of that one too when done. You can see the stain (greenish) being applied on the YouTube link. This Guitar has the CNCed top.

I am always keen to get feedback (whatever the flavour) so please let me know what you think.