falcate Failure with an unexpected result

falcate Failure with an unexpected result

An Interesting failure or rather an unexpected result for me to learn from and think about.

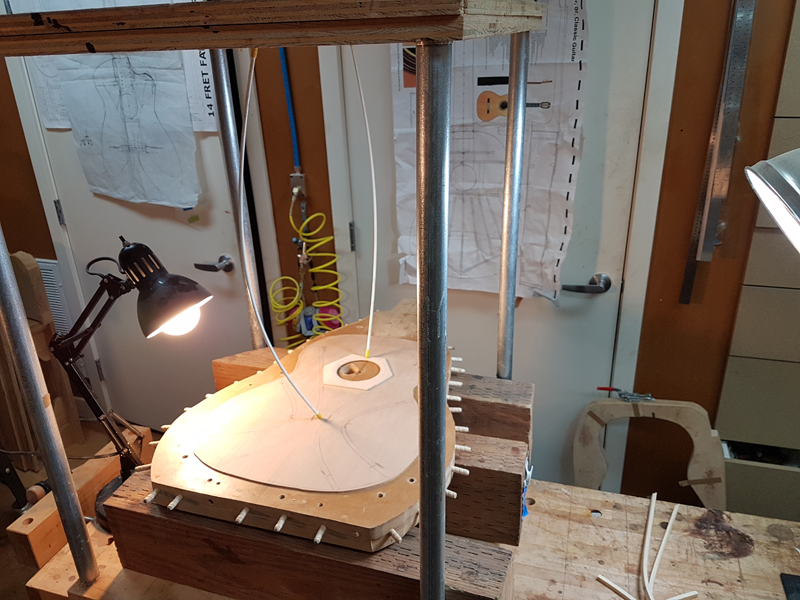

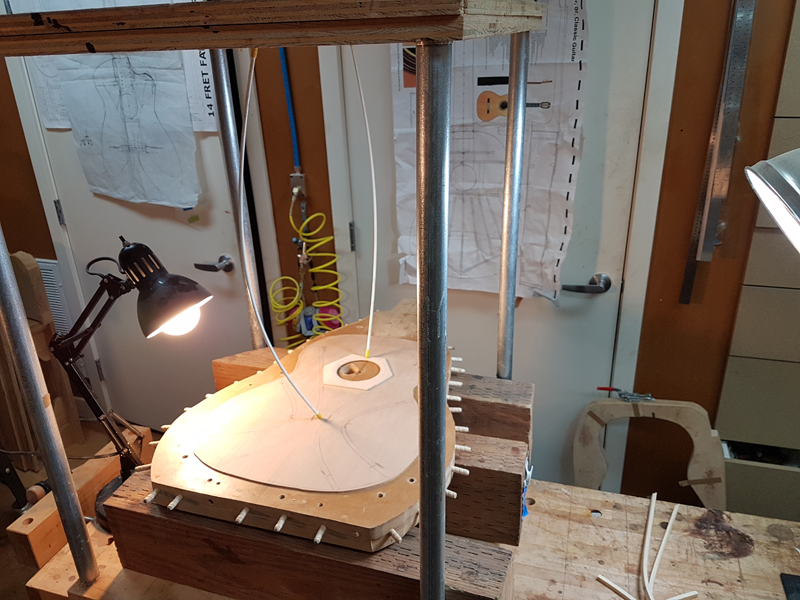

In 2012, I made this guitar.

viewtopic.php?f=25&t=4786&p=56161&hilit ... dar#p56161

It has been my "go to guitar" for almost 5 years now, however I was replacing the strings a couple of weeks ago when, as I bought the strings into tune I heard a loud bang.stopping and wondering what had happened I could see no problems at all,everything looked fine, so I slowly continued expecting the problem to make itself obvious but tuning went without incident. It came into tune and everything looked OK, I played it, beautiful.

But I knew something wasnt right, possibly a brace. Two weeks went by with no problems,no tuning problems nothing, except that after the two weeks the bridge appeared to have rolled forward, but only slightly and a slight dip in the soundboard between the bridge and soundhole , so I removed the strings and got my hand into the soundhole, felt around the intermediate falcates,they seemed good, but then noticed the primary falcates had come away from the soundboard leaving the CF still firmly attached to the soundboard, the primary brace on the treble side had come away completly in the lower bout up to the soundhole side of the bridge plate, also the primary on the Bass side had also come free from around the same area but with about the last inch still attached in the lower bout.

Not happy with myself and preparing for a new top, I thought I have nothing to lose by attempting a repair, and not wanting to attempt a reglue with resin ( I could see a major mess) I decided on CA, small tube of super glue through the sound hole and to my amazment I was able to reglue both braces down again along their length, I have had it restrung now for a couple of days and everything looks to be good,but time will tell and it may yet need that new top.

What really has me amazed,was how well the guitar (Soundboard) stood up to this sort of failure, the sound didnt seem to change ( to my ear) and apart from an increase in bridge rotation the dip and the bang, I never would have known anything was wrong.

Thoughts & comments appreciated.

In 2012, I made this guitar.

viewtopic.php?f=25&t=4786&p=56161&hilit ... dar#p56161

It has been my "go to guitar" for almost 5 years now, however I was replacing the strings a couple of weeks ago when, as I bought the strings into tune I heard a loud bang.stopping and wondering what had happened I could see no problems at all,everything looked fine, so I slowly continued expecting the problem to make itself obvious but tuning went without incident. It came into tune and everything looked OK, I played it, beautiful.

But I knew something wasnt right, possibly a brace. Two weeks went by with no problems,no tuning problems nothing, except that after the two weeks the bridge appeared to have rolled forward, but only slightly and a slight dip in the soundboard between the bridge and soundhole , so I removed the strings and got my hand into the soundhole, felt around the intermediate falcates,they seemed good, but then noticed the primary falcates had come away from the soundboard leaving the CF still firmly attached to the soundboard, the primary brace on the treble side had come away completly in the lower bout up to the soundhole side of the bridge plate, also the primary on the Bass side had also come free from around the same area but with about the last inch still attached in the lower bout.

Not happy with myself and preparing for a new top, I thought I have nothing to lose by attempting a repair, and not wanting to attempt a reglue with resin ( I could see a major mess) I decided on CA, small tube of super glue through the sound hole and to my amazment I was able to reglue both braces down again along their length, I have had it restrung now for a couple of days and everything looks to be good,but time will tell and it may yet need that new top.

What really has me amazed,was how well the guitar (Soundboard) stood up to this sort of failure, the sound didnt seem to change ( to my ear) and apart from an increase in bridge rotation the dip and the bang, I never would have known anything was wrong.

Thoughts & comments appreciated.

- Trevor Gore

- Blackwood

- Posts: 1607

- Joined: Mon Jun 20, 2011 8:11 pm

Re: falcate Failure with an unexpected result

Interesting! So the falcate brace didn't fail, but the glue line did?

Obviously impossible to tell what the cause of the problem might have been, other than a glue line failure. Starved joint? Joint moved once gelled? How was the fit of the braces over the bridge plate? Good epoxy joints, like most glue joints, are usually stronger than the wood.

I still have the original prototype falcate guitar, now 12 years old, and under tension all that time. Still in great condition.

Good save with the CA. Keep us posted on how it holds up.

Obviously impossible to tell what the cause of the problem might have been, other than a glue line failure. Starved joint? Joint moved once gelled? How was the fit of the braces over the bridge plate? Good epoxy joints, like most glue joints, are usually stronger than the wood.

I still have the original prototype falcate guitar, now 12 years old, and under tension all that time. Still in great condition.

Good save with the CA. Keep us posted on how it holds up.

Fine classical and steel string guitars

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Re: falcate Failure with an unexpected result

Yes Trevor, Sorry about that I should have worded it better, It was a glue line failure not a brace failure.

Also I should have mentioned that it has not had an easy life, it has been gigged it has been to many barbies and Jams, It has had beer over it, and was once dropped by a clown from about waist height onto its tail. I am not looking for an excuse here, I feel that I may have starved the joint, Possibly .

Really I should have looked after it better.

I only posted because I thought it would be interesting to builders,as to how it stood up without the structural strength of the primary braces, I would have thought it would have collapsed more so toward the sound hole, but it held its own, telling me that the intermediate braces play a bigger part in the structural integrity than I was giving them credit for.

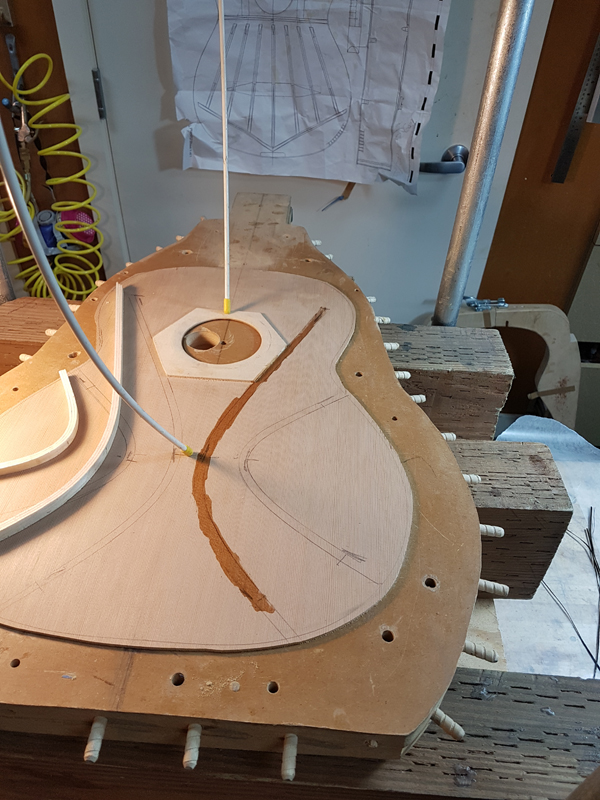

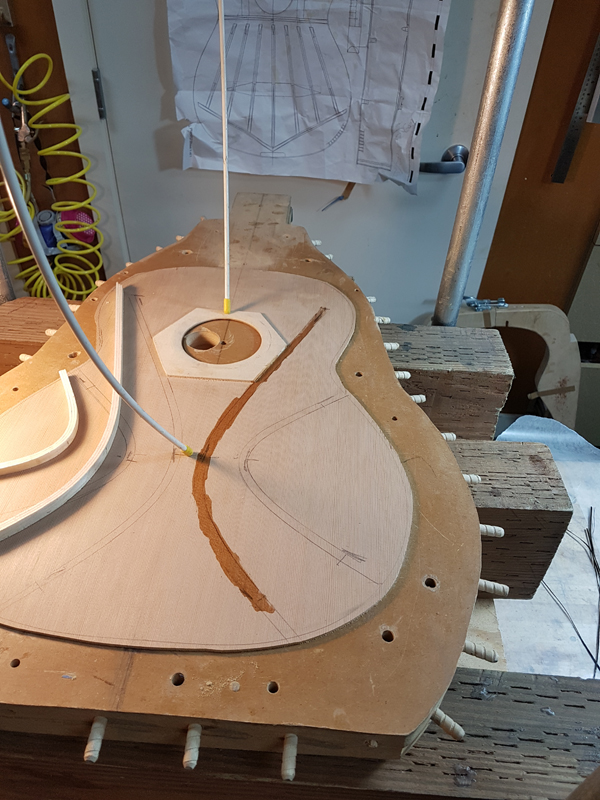

I have just finished bracing another one and if its anything like this I will be very happy, I also took a bit more care with the glue joint on this one , however i find it hard to judge just the right amount to prevent squeeze out which looks messy and not enough that possibly caused this problem.

Thanks for the design mate Its a winner.

Cheers Tod Gilding

Also I should have mentioned that it has not had an easy life, it has been gigged it has been to many barbies and Jams, It has had beer over it, and was once dropped by a clown from about waist height onto its tail. I am not looking for an excuse here, I feel that I may have starved the joint, Possibly .

Really I should have looked after it better.

I only posted because I thought it would be interesting to builders,as to how it stood up without the structural strength of the primary braces, I would have thought it would have collapsed more so toward the sound hole, but it held its own, telling me that the intermediate braces play a bigger part in the structural integrity than I was giving them credit for.

I have just finished bracing another one and if its anything like this I will be very happy, I also took a bit more care with the glue joint on this one , however i find it hard to judge just the right amount to prevent squeeze out which looks messy and not enough that possibly caused this problem.

Thanks for the design mate Its a winner.

Cheers Tod Gilding

- Trevor Gore

- Blackwood

- Posts: 1607

- Joined: Mon Jun 20, 2011 8:11 pm

Re: falcate Failure with an unexpected result

Yep, that's a tough one. Don't worry too much about the squeeze out that just looks messy. At least you know you've got enough glue in there. However, it's a problem when the tow floats out with the squeeze out. I guess practicing on a few short, straight dummy braces will give you an improved feel for it. It should look something like this, with a meniscus of epoxy squeeze out at the base of the brace.

Someone suggested machining a small groove in the brace (for example with a small diameter veining bit) and laying the tow in that before positioning the brace, in the hope that there is much less propensity for the tow to squeeze out. I've never tried it, but if you have continuing problems, it may be something to check out.

Fine classical and steel string guitars

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Re: falcate Failure with an unexpected result

Someone is actually doing this.....I have a vague memory of mention of it by a student on one of Strato's building course. Ive been giving it serious consideration for my next build.Trevor Gore wrote: ↑Tue Aug 29, 2017 10:55 pm

Someone suggested machining a small groove in the brace (for example with a small diameter veining bit) and laying the tow in that before positioning the brace, in the hope that there is much less propensity for the tow to squeeze out. I've never tried it, but if you have continuing problems, it may be something to check out.

Martin

- Trevor Gore

- Blackwood

- Posts: 1607

- Joined: Mon Jun 20, 2011 8:11 pm

Re: falcate Failure with an unexpected result

I have a vague recollection that it might have been a suggestion by Craig Bumgarner, but happy to be corrected.

Fine classical and steel string guitars

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

- lamanoditrento

- Blackwood

- Posts: 585

- Joined: Thu May 05, 2016 9:50 am

Re: falcate Failure with an unexpected result

I know for certain that Andrew does at his school and fairly sure Matin was doing this as well. The way Andrew explained it, not all student get hopelessly addicted to lutherie  so will never have a chance to improve on their next one. The channel cut with a dremmel and a jig was to keep the tow under the brace as they tend never to have a problem with a starved joint.

so will never have a chance to improve on their next one. The channel cut with a dremmel and a jig was to keep the tow under the brace as they tend never to have a problem with a starved joint.

Trent

Re: falcate Failure with an unexpected result

Any chance of some pics of the Dremel jig Trent? No problems if Andrew would rather keep it in-houselamanoditrento wrote: ↑Wed Aug 30, 2017 9:32 pmI know for certain that Andrew does at his school and fairly sure Matin was doing this as well. The way Andrew explained it, not all student get hopelessly addicted to lutherieso will never have a chance to improve on their next one. The channel cut with a dremmel and a jig was to keep the tow under the brace as they tend never to have a problem with a starved joint.

Martin

Re: falcate Failure with an unexpected result

I was thinking along the same lines (putting a groove in the braces) after discovering the difficulty of getting the correct amount of epoxy during my first falcate build. Too much glue and the CF tow floats out. Too little and the brace may fail or not achieve full composite action between the wood and CF.

I figured that it could work for the minor falcate braces but, for the main falcates, doesn't the CF tow that goes between the brace and the top go under the bridge plate? So how can you glue the tow to the brace before gluing the brace to the top? Am I missing something?

I figured that it could work for the minor falcate braces but, for the main falcates, doesn't the CF tow that goes between the brace and the top go under the bridge plate? So how can you glue the tow to the brace before gluing the brace to the top? Am I missing something?

Richard

- Trevor Gore

- Blackwood

- Posts: 1607

- Joined: Mon Jun 20, 2011 8:11 pm

Re: falcate Failure with an unexpected result

Yes.

The AGMS guys put the bridge plate on in three pieces; between the braces rather than under them. Can't say I'm a fan of that, but I guess it's better than having gappy "joints" between the primary falcates and the bridge plate, which is what they're trying to avoid.

Fine classical and steel string guitars

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Re: falcate Failure with an unexpected result

Any reason the tow couldn't go _over_ the bridge plate CF matting layer?

Martin

- lamanoditrento

- Blackwood

- Posts: 585

- Joined: Thu May 05, 2016 9:50 am

Re: falcate Failure with an unexpected result

I am sure Andrew wouldn't mind but I don't have a pic on my phone so will have to take one when I get back to Brisbane. The demmel is held upside down and the bit potrudes between a fence and an adjustable pivot to keep the bit centre along the curve of the falcate.

The Brisbane school has moved to a single bridge plate with notches and the paints a thin coating of epoxy on the under side of the brace. Then laying a epoxy coated tow in the groove before placing it on the soundboard.

Trent

- Steve.Toscano

- Blackwood

- Posts: 489

- Joined: Thu Feb 07, 2013 11:43 pm

- Location: Port Stephens NSW

Re: falcate Failure with an unexpected result

Just to clarify, not all the AGMS schools do this. I believe its only Strato who gets his students to do it this way nowadays.Trevor Gore wrote: ↑Thu Aug 31, 2017 7:58 pmThe AGMS guys put the bridge plate on in three pieces; between the braces rather than under them. Can't say I'm a fan of that, but I guess it's better than having gappy "joints" between the primary falcates and the bridge plate, which is what they're trying to avoid.

The reason is, as Trevor alluded to, it's far easier for a student (most who have never touched a chisel prior to attending the school) to use this method rather then attempt to notch the braces to a tight fit.

I myself have started to get my students to make the falcates extra tall, notch them, and if they take too much out (most do) i then get them to plane the bottom of the whole brace to bring the notch back down to a tight fit. They then plane the brace height down to size right before applying the top layer of CF.

- Trevor Gore

- Blackwood

- Posts: 1607

- Joined: Mon Jun 20, 2011 8:11 pm

Re: falcate Failure with an unexpected result

None at all. Whatever you find easier to deal with.

That's a good approach for the novice builder.Steve.Toscano wrote: ↑Thu Aug 31, 2017 11:09 pmI myself have started to get my students to make the falcates extra tall, notch them, and if they take too much out (most do) i then get them to plane the bottom of the whole brace to bring the notch back down to a tight fit. They then plane the brace height down to size right before applying the top layer of CF.

Fine classical and steel string guitars

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

- lamanoditrento

- Blackwood

- Posts: 585

- Joined: Thu May 05, 2016 9:50 am

Re: falcate Failure with an unexpected result

Martin

-

johnparchem

- Blackwood

- Posts: 547

- Joined: Mon Jan 21, 2013 2:59 am

- Location: Seattle

- Contact:

Re: falcate Failure with an unexpected result

On my latest guitar I am slotting the bottom of the falcate braces for the carbon fiber. It really made the glue up process go a lot better for me. At the Guild of American Luthier auction I bought a router base\table called the Otter by the maker of Luthiers friend. http://www.luthiersfriend.com/aOtter/Otter.html. I modified the base by putting in a flat fence.

I cleaned up the brace on a flat sanding disk and made sure that the slot was not too deep.

I would apply epoxy to the bottom of the brace, wet the tow with my gloved fingers and lay the CF into the slots on the bottom of the braces. I would paint the brace path with epoxy and then position and clamp down the braces. with this method I had no floating CF squeezing out from under the brace.

Time to clean my shop

I cleaned up the brace on a flat sanding disk and made sure that the slot was not too deep.

I would apply epoxy to the bottom of the brace, wet the tow with my gloved fingers and lay the CF into the slots on the bottom of the braces. I would paint the brace path with epoxy and then position and clamp down the braces. with this method I had no floating CF squeezing out from under the brace.

Time to clean my shop

- Trevor Gore

- Blackwood

- Posts: 1607

- Joined: Mon Jun 20, 2011 8:11 pm

Re: falcate Failure with an unexpected result

Dare I say it....

Groovy!

Groovy!

Fine classical and steel string guitars

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

-

johnparchem

- Blackwood

- Posts: 547

- Joined: Mon Jan 21, 2013 2:59 am

- Location: Seattle

- Contact:

Re: falcate Failure with an unexpected result

I was feeling groovy, All and all it was a easier process. When I carved away parts of the braces I found no gap between the brace and the CF or the CF and the top.

Re: falcate Failure with an unexpected result

Would another approach to this problem be to glue the CF tow to the sound board, wait until it dries, then glue the brace on. The CF tow and epoxy can be flattened to a minimal thickness (I would imagine 0.1 to 0.2 mm) and flattening with a small plastic trowel is a good way to ensure that the fibres are fully saturated with epoxy all round. The epoxy has "gap filling" capability. I'm not sure about the bond between new and cured epoxy but my guess would be that it is strong enough. This approach would take a little longer, but so does forming grooves in the falcate braces.

Any thoughts or comments?

Any thoughts or comments?

Richard

Re: falcate Failure with an unexpected result

Sounds like extra work. You'' find that after a few jobs you get the hang of putting on just enough epoxy and just the right amount of tow to end up with a half decent job. A small artists brush Ive found is the best tool to work the tow into the epoxy and also to tease out the ends of the tow runs.Woodsy23 wrote: ↑Thu Mar 08, 2018 1:13 pmWould another approach to this problem be to glue the CF tow to the sound board, wait until it dries, then glue the brace on. The CF tow and epoxy can be flattened to a minimal thickness (I would imagine 0.1 to 0.2 mm) and flattening with a small plastic trowel is a good way to ensure that the fibres are fully saturated with epoxy all round. The epoxy has "gap filling" capability. I'm not sure about the bond between new and cured epoxy but my guess would be that it is strong enough. This approach would take a little longer, but so does forming grooves in the falcate braces.

Any thoughts or comments?

Martin

- Trevor Gore

- Blackwood

- Posts: 1607

- Joined: Mon Jun 20, 2011 8:11 pm

Re: falcate Failure with an unexpected result

I'm pretty sure there is a time window for applying epoxy over epoxy according to the WEST instructions, and I think it is pretty short (like not long after it's gelled). You might want to check that. Otherwise you need to do a surface prep before you apply more epoxy.

The book method or the groove method (I haven't heard any bad reports about it, e.g. brace detachments) seem to be the best options.

Fine classical and steel string guitars

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Who is online

Users browsing this forum: No registered users and 41 guests