Here is a method that will give you accurately sized pieces, and more importantly allow you to do so while minimizing a serious injury. Note My riving knife and blade guard have been removed to make the procedure easier to photograph. I also make my own zero clearance blade inserts. These make most tasks on a table saw much safer than using the stock insert that has a huge throat that will allow stray pieces to come flying back at you.

First up you will need a feather board. Easily made, or buy one if your flush with cash. You must place the feather board so that it is entirely in front of the blade. This allows the narrow strip to move away from the blade as it is cut.

Notice that the feather board is place to the left side of the blade the desired thickness of the piece that I'm wanting to cut. Now all you need to do is fit the piece that you are going to cut against the feather board, then bring the fence up against the board. Just snug, you don't want to force the piece against the feather board. This will end up making the strip wider than you want.

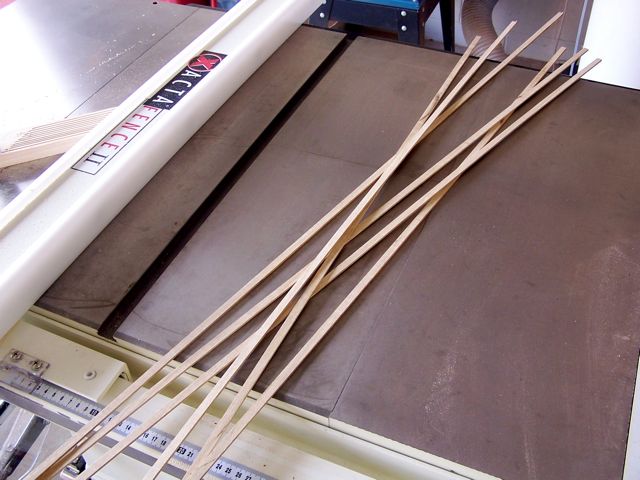

After each strip is cut, repeat fitting the wood against the feather board and adjusting the fence. You'll have to judge how narrow you are willing to go with the piece you are cutting. I've gone down to 5 mm between the fence and the blade, but you will want to have your wits about you.

All that's left is to give them a light pass through the drum sander.

Hope that this helps, and gives you some inspiration for other uses for a feather board.